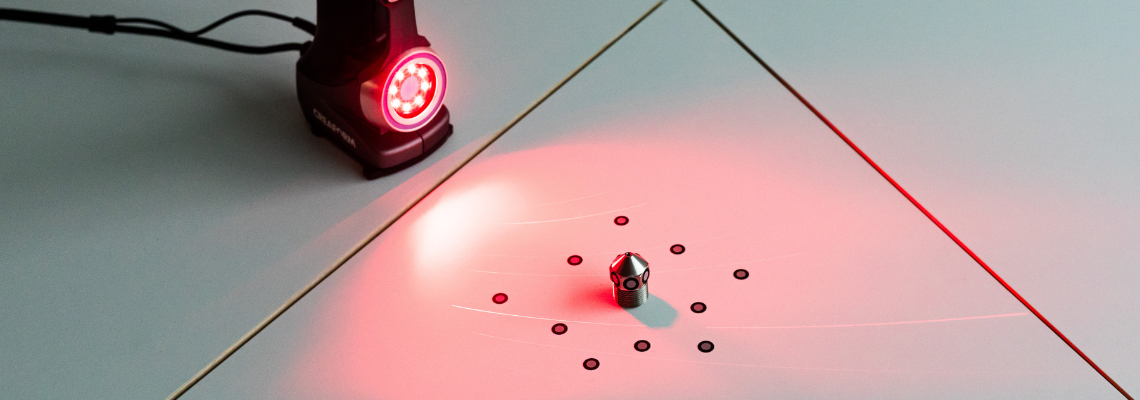

The laboratory’s activities include the development of robotic systems/assistants, including the generation of case-specific ideas, design, computer modelling, prototyping and experimental testing, and the application of robotic systems to improve people’s working, daily or specific activities, including the development of new materials and processes using state-of-the-art computational, AI-based design and 3D scanning systems for process control. The laboratory also develops customised multi-material biocomposite structures using robotic hybrid additive manufacturing for health and transport technology applications, such as the development of customised splints, helmets, protective masks, handles, housings, etc. The developed technology will enable the market to benefit from a faster, more cost-effective and environmentally friendly production process for customised structures compared to conventional polymeric manufacturing technologies (e.g. injection moulding).